Our range of Ensafe mesh balustrade is generally used as the best solution to secure people and vehicles as well as minimize the potential falling dangers in bridges, path and stairs. It is composed of several modular panels - stainless steel cable mesh that twisted around rectangular or diamond tubular frame.

For easy shipment, our range of Ensafe mesh balustrade panels is transported in detached type that requires to be assembly. Here we offer a guidance about mounting infill cable mesh to the tubular frame as shown below:

Step 1 Preparation

As to long-span frames, support posts are needed to mount to this frame prior to assembly. additionally, inserting temporary support members between the horizontal frame members is another choice to protect the frame from collapsing under tension.

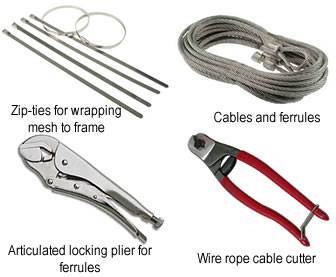

Prepare tools required during the mounting process as shown in the right picture. For workers, a pair of gloves are also required to protect their hands from being hurt.

Step 2 Mounting

Lay the tubular frame of balustrade panels on a clean floor and make sure the access is left on all four sides for easy mounting cable mesh to this tubular frame.

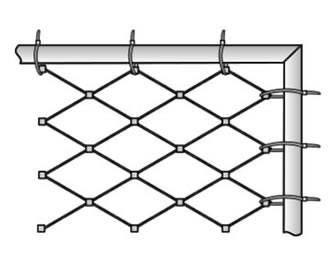

Mount cable mesh to the frame using zip-ties which make it convenient to install. Meanwhile, these zip-ties helps to give an idea of the final proportions of the diamonds.

Note:

Make sure the edge diamonds are located according to the requirements of final tension.

Step 3 Attach & tension

Prepare mounting cables that are long enough to wind the tubular frame. Normally, the length is about 2.5 times of the circumference of your tubular frame.

Remove the zip-ties, string the mounting cable through open corner ferrule, wrap the cable around the tubular frame and then string it to the next open ferrule as shown in the right picture.

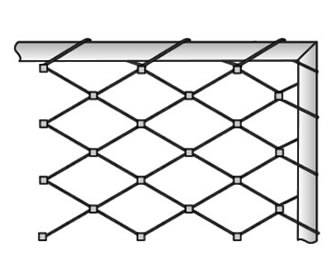

Repeat above action, adjust the tension of the net.

Step 3 Attach & tension

Prepare mounting cables that are long enough to wind the tubular frame. Normally, the length is about 2.5 times of the circumference of your tubular frame.

Remove the zip-ties, string the mounting cable through open corner ferrule, wrap the cable around the tubular frame and then string it to the next open ferrule as shown in the right picture.

Repeat above action, adjust the tension of the net.

Step 4 Final tension adjustment

The final tension adjustment should be applied after finishing string and winding cable to the last side of the frame. Align all open ferrules along the interior of the frame and cut the remaining rope ends.

Then mounting this assembled cable mesh infill panel to the post.

how can we help you?

Contact Boegger Industech Limited or submit a problem.