Patent

Boegger Industech Limited, established in 1999, is a leading enterprise in the stainless steel rope and rigging industry integrating product development, production and sales. The company has more than 300 employees and an annual industrial output value of more than $16 million. In 2022, it produced and sold 90,000 tons of steel wire ropes, 20,000 tons of steel wires, and 2,000 tons of rigging.

We have more than 30 industrial design and utility model patents from China and 5 design patents from the United States. Product types cover more than 3,000 products in three categories: construction, shipbuilding and industrial products, involving yachts and ships, indoor and outdoor decoration, highways, bridge engineering, safety protection, outdoor development and other fields.

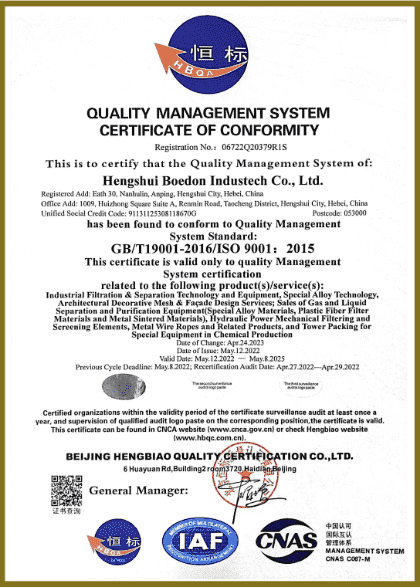

Boegger is certified by GB/T 19001-2016/ISO9001:2015. We have our own spectrometer, tensile testing machine, salt spray testing machine and other testing instruments. With the support of the MES system, the company has more than 150 sets of automation equipment and 2 CNC machining lines, successfully operating Boegger into a "smart factory", with informatization of the entire manufacturing process, production visualization, and process standardization.

We have an independent professional R&D team of 20 technical R&D personnel, 5 with intermediate and senior professional titles, which guarantee Boegger to effectively and efficiently provide ODM, OEM and OBM services to global clients.

Patent & Certificate

Patent

Certificate

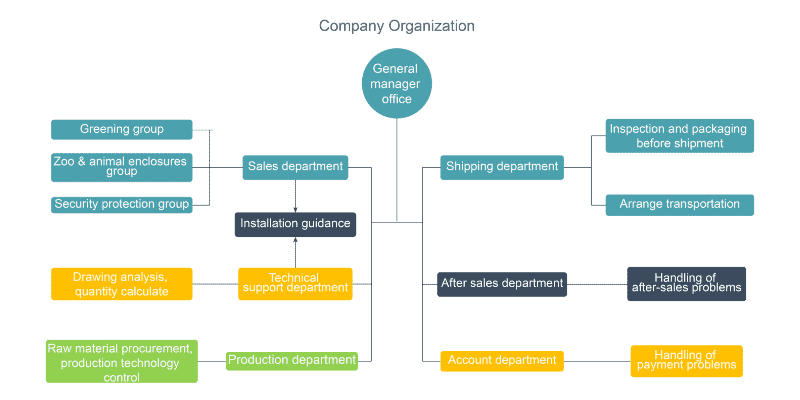

Company Organization

Equipment & Workshop

Raw material warehouse for rigging

Raw material warehouse for wire ropes

Raw material warehouse for turnbuckles

Production equipment workshop for rigging

Production equipment workshop for wire ropes

Production equipment workshop for cable mesh

Finished cable mesh

Rigging engraving

Wire rope tensile strength testing

Plastic packaging of rigging

Rigging carton packaging

Tight type packaging

Loose type packaging

Service

Suitable material, wire diameter, mesh aperture, mounting method and accessories are recommended according to the use environment and place.

A professional technical team is available to provide detailed drawings and post installation guide.

An order confirmation document will be sent to reconfirm the details before production.

Raw material test report, product test photo & product test report.

List of materials, installation drawings & customized labels for easy post installation.

Partners

how can we help you?

Contact Boegger Industech Limited or submit a problem.